Today’s rolling stock depends on increasingly complex embedded systems to run and monitor onboard equipment, increase safety and reliability, enhance passenger comfort, and deliver new services. Train designers and operators must install and maintain multiple systems throughout a train to meet these needs. These systems must process massive amounts of data under space and power constraints in harsh environments. They must meet high system reliability requirements and stringent industry regulations.

This article considers the advantages of consolidating operational functions on a robust, cost-effective 3U CompactPCI Serial single board computer (SBC). We discuss the challenges of designing an SBC for running virtualized solutions on rolling stock. We examine how a manufacturer like MEN Mikro Elektronik meets these challenges with a rugged SBC design. We investigate how the latest members of the Intel® Xeon® processor D-1500 product family enable these SBCs to deliver the scalability and performance required to securely virtualize multiple workloads. And we look at how these processors support secure, high-speed data transfer.

The Advantages of System Consolidation for Rolling Stock

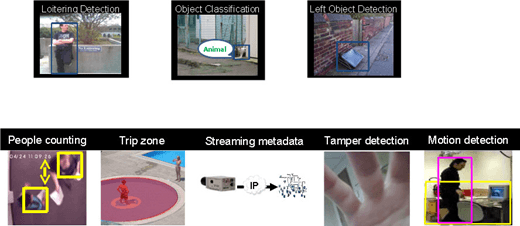

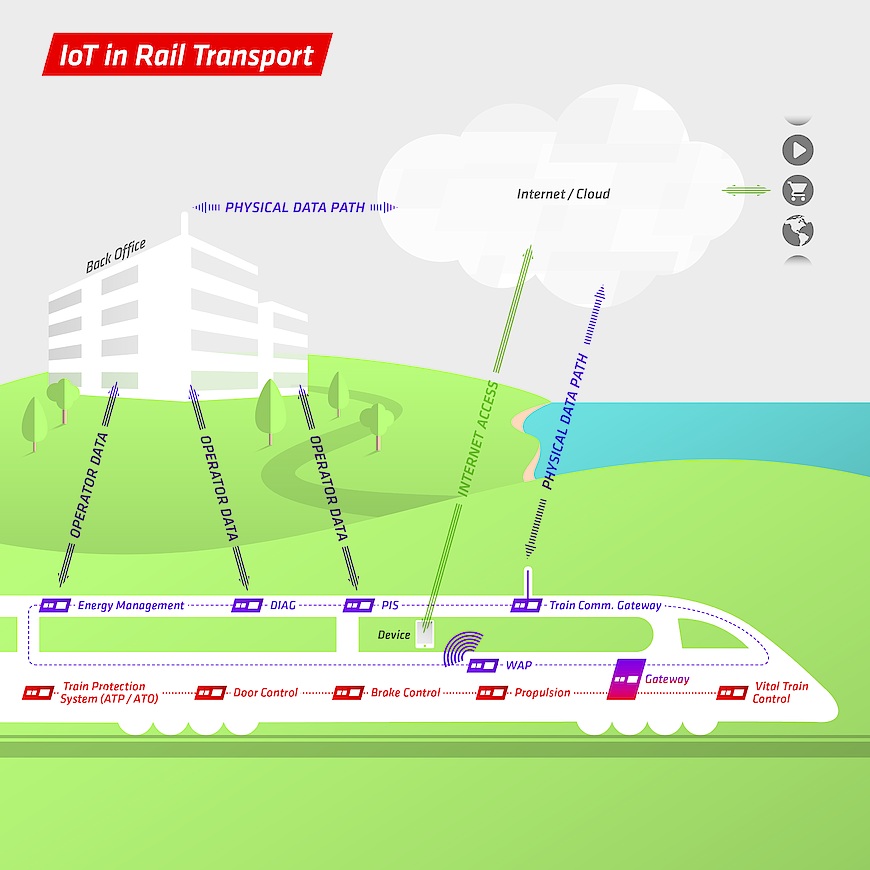

Modern trains depend on multiple embedded systems. These systems must run a variety of applications simultaneously and in real time, many of which are critical to safety and passenger comfort (Figure 1).

Figure 1. Modern trains depend on a variety of applications that need to run simultaneously, require real-time performance, and are critical to safety and passenger comfort.

Examples of these applications include:

- Communications

- Advanced braking control and signaling

- Passenger information systems (PIS) and entertainment

- Internet wireless access points (WAP)

- Video surveillance

- Diagnostic and preventive maintenance

- Electronic ticketing

Running each application on a separate system requires mounting space, mountings, cabling, power, and security for each individual unit. It also means maintaining multiple systems with multiple architectures – an IT nightmare that often results in replacing entire units to keep up with system advances.

Using virtualization to create a layer of abstraction between computer hardware systems and software enables train system designers to consolidate multiple application workloads on fewer physical systems. This consolidation saves space and reduces equipment, energy, and management costs.

Advantages of virtualization for rolling stock include:

- Improved utilization of compute resources (compared to multiple systems operating at fractional capacity)

- One platform instead of many to manage and secure

- Easier and less expensive upgrades than always replacing the “box”

- Ability to separate critical operations from less-sensitive applications

- Less complex, more affordable implementations of redundancy

Designing a Consolidation Platform for Trains

Embedded systems in trains need to fulfill extensive and specific requirements that go far beyond those in general-purpose IT infrastructures. For instance, life on the rails is much different than the consistent conditions of a server room. Rolling stock embedded systems must withstand shock, vibration, and temperature variances, plus accommodate an environment where power and space are at a premium. In addition, since trains are responsible for the safety of hundreds of passengers, system security and availability are paramount. Finally, to deliver essential services, virtualization solutions running on these systems must ensure that their functions and code have the dedicated compute, memory, and network resources necessary for reliable performance.

A Rugged, Safe SBC for Transport

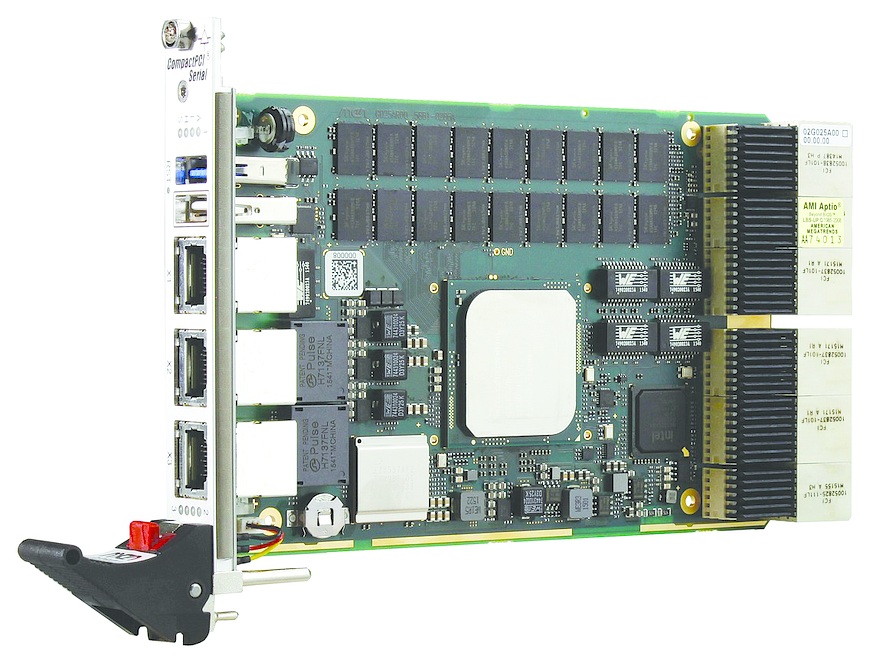

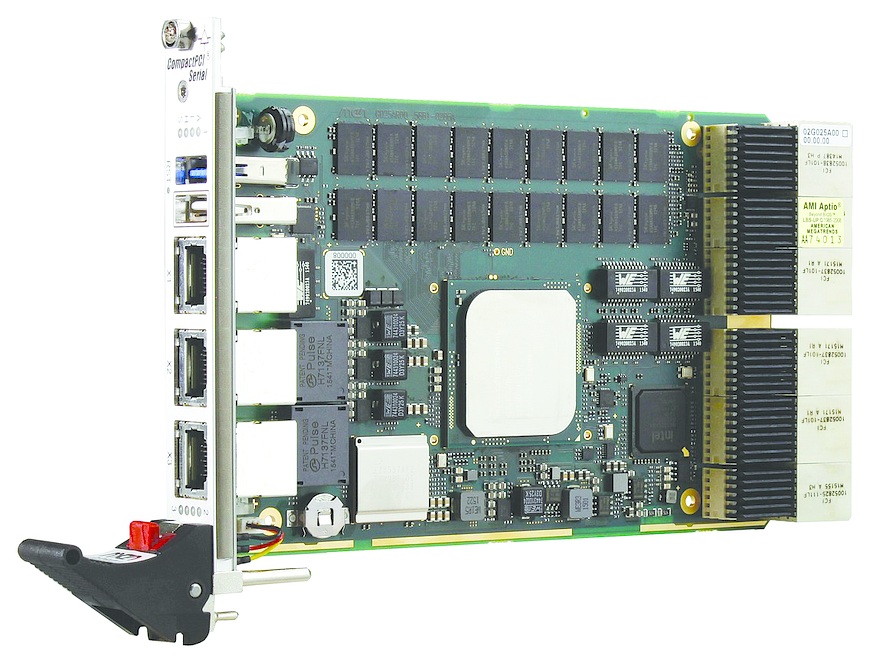

MEN Mikro’s latest platform for rolling stock, the G25A 3U CompactPCI Serial SBC, meets all these requirements (Figure 2). The SBC features a rugged design complete with M12 connectors and soldered components for exceptional shock and vibration resistance. Optional conformal coating provides extra protection from moisture, dust, and chemical contaminants.

Figure 2. The MEN Mikro G25A 3U CompactPCI Serial SBC offers a choice of RJ45 or M12 connectors. The latter is recommended for rolling stock.

An extended operating temperature range enables the G25A to handle harsh environments. Ordering the G25A with a heat sink and conductive cooling frame enhances reliability under heat.

The SBC complies with essential environment regulations for rolling stock, including EN 50155, the international standard for railway applications. In fact, MEN Mikro is one of less than 10 companies worldwide certified according to the quality management systems EN 9100 (transportation) and International Railway Industry Standard (IRIS), in addition to ISO 9001. Train manufacturers associated with IRIS commit to using only IRIS-certified subcontractors.

Designed for Performance

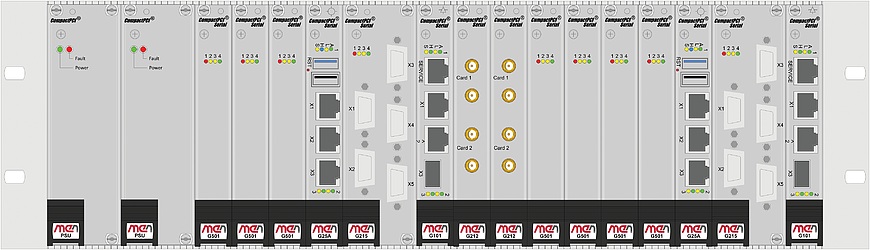

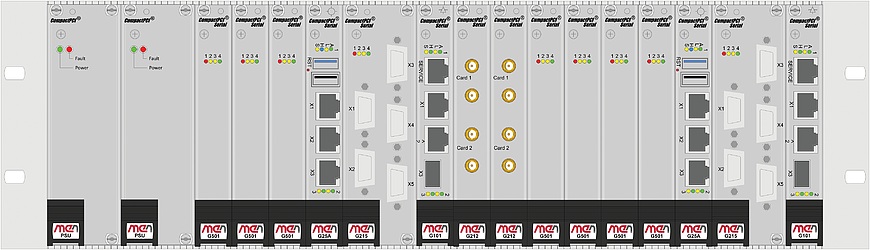

The G25A’s ability to meet performance requirements starts with its form factor. Intended as an industrial standard for mobile and stationary applications in control and monitoring, 3U CompactPCI Serial uses fast serial point-to-point connections to deliver extremely high bandwidth, making it particularly well suited for high-speed data communication applications. With no switches or bridges required for a typical configuration of one system slot and up to eight peripheral slots, the form factor reduces complexity and cost. As with the original CompactPCI specification, CompactPCI Serial supports hot swapping for fast component replacement.

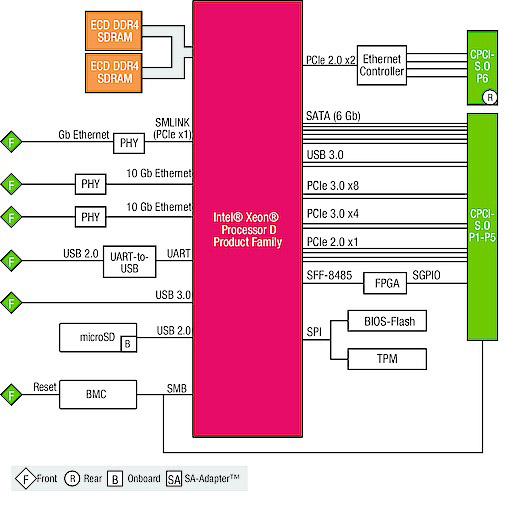

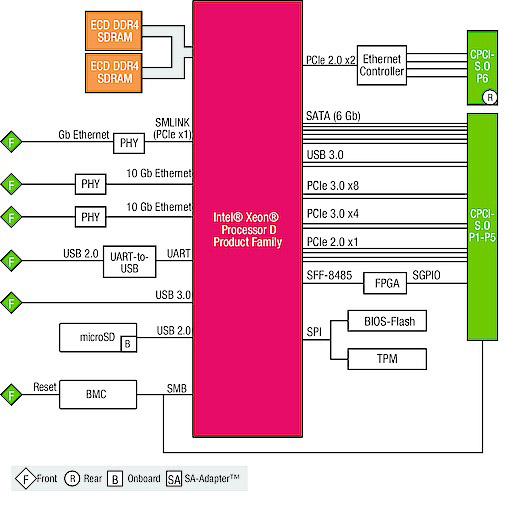

Within a chassis, the G25A provides PCI Express links, SATA/SAS, USB, and Ethernet interfaces, plus signals for general system management (Figure 3). Each companion slot can support additional Ethernet interfaces to build a full-mesh interconnect without an external switch. All interfaces are accessible at the same time. For very intensive computing tasks, designers can cluster up to four G25As in a single system.

Figure 3. Within a chassis, the G25A provides PCI Express links, SATA/SAS, USB, and Ethernet interfaces, plus signals for general system management.

The Right Fit for Many Applications

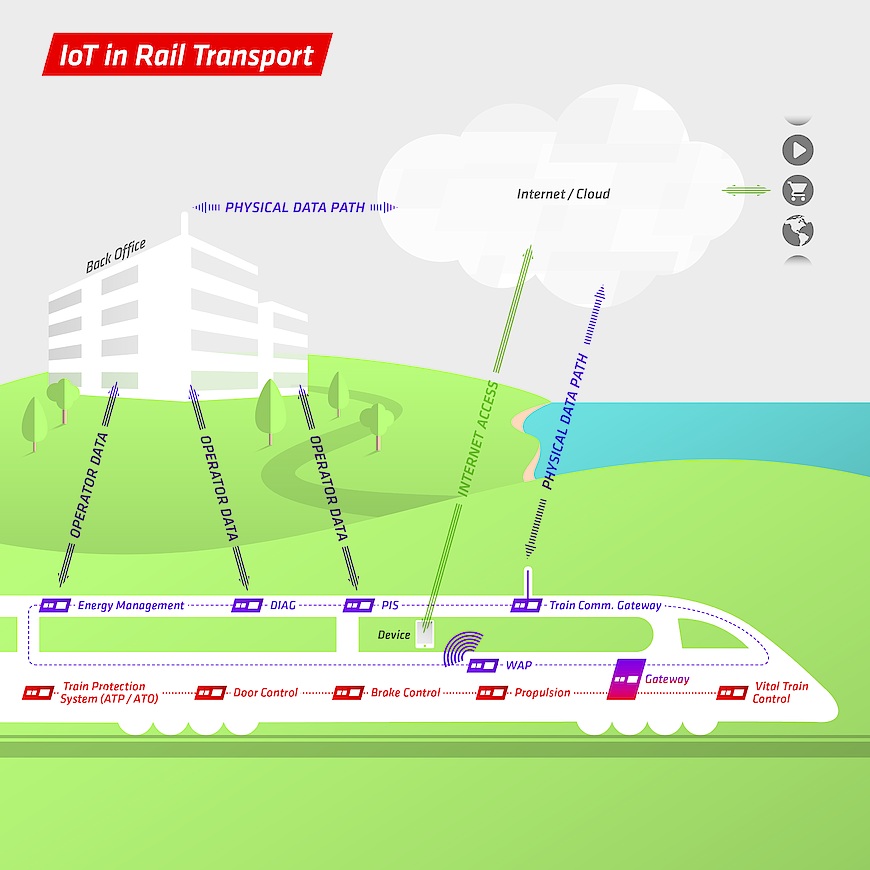

As the SBC within a train computer chassis, the G25A can reliably perform mission-critical tasks, mechanical system monitoring, video surveillance tasks, passenger infotainment needs, and data and voice transmissions between the vehicle, wayside equipment, and the control center. The SBC’s high compute density, 32 GB DDR4 DRAM capacity, extensive I/O, and processor-based Intel® Virtualization Technology (Intel® VT-x) make it an ideal platform for consolidating a wide mix of rolling stock system functions (Figure 4).

Figure 4. The Men Mikro G25A’s combination of high compute density, up to 32 GB DDR4 DRAM, extensive I/O, and processor-based Intel® Virtualization Technology (Intel® VT-x) make it an ideal platform for system consolidation.

Typical network-attached storage (NAS) systems, RAID setups, or Internet access systems can be easily realized. Designers can combine the functionality of multiple systems in one rack – each block controlled by one G25A.

As an example, designers could combine a passenger entertainment server, PIS, electronic ticketing application, and door control system on one G25A. On a second G25A, they could combine a network video recorder system and an Internet access system performing vehicle-to-land communication and diagnosis data transfers. Other slots in the chassis enable the addition of peripheral cards for adding storage, interfaces, and switches.

Availability, Security, and Reliability

To increase system availability, designers can use a virtual machine monitor (VMM) to control two G25As connected via Ethernet cables. According to needs, the complete system could run as redundant systems or as a single system providing double capacity.

The G25A addresses security through processor-based solutions and inclusion of a Trusted Platform Module (TPM) for cryptography. Error-correcting code (ECC) memory, a baseboard management controller (BMC), and a watchdog timer contribute to the SBC’s high reliability.

A Processor Family for Virtualization and High-Speed Data Transfer

Train system integrators can order the G25A with either the Intel® Xeon® processor D-1577 (16 cores) or D-1539 (8 cores). The more cores, the greater the system’s potential for workload consolidation.

Both processors provide built-in hardware virtualization through Intel® VT-x to enable dynamic provisioning of services (processor cores, memory, and I/O) for isolated workloads and simultaneous operation of real-time and non-real-time applications. By providing hardware assistance to the virtualization software, Intel VT-x reduces the software’s size and complexity, enabling more economical, efficient, secure, and powerful virtualization solutions.

Intel VT-x consists of technology components that support virtualization of Intel® processor-based platforms, enabling running different operating systems and applications in independent partitions. Each partition behaves like a virtual machine (VM) and provides isolation and protection across partitions. This hardware-based virtualization, along with appropriate virtualization software, enables true workload isolation.

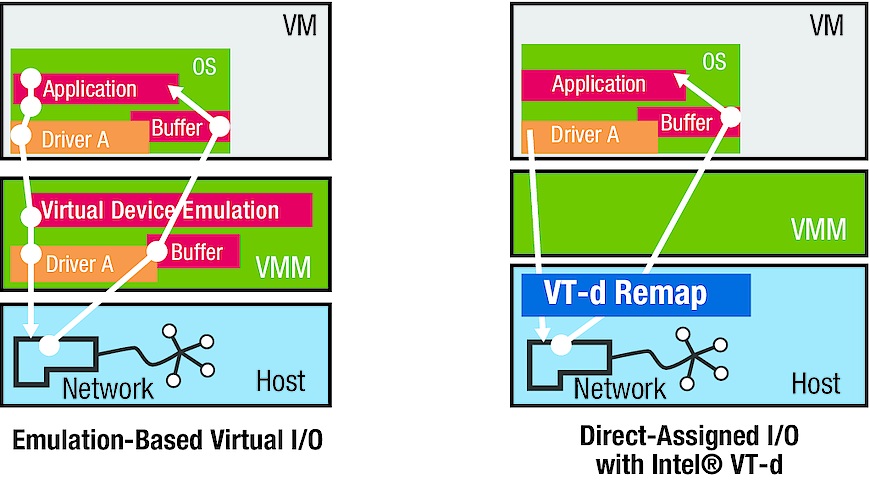

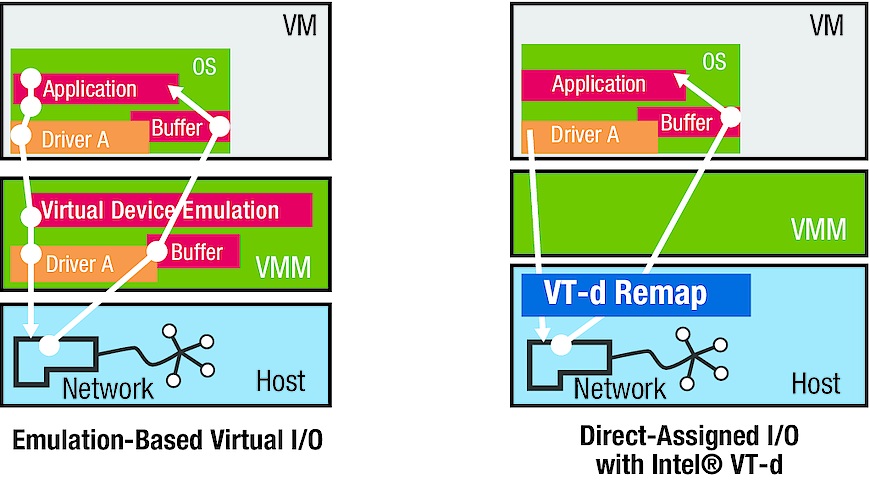

Like many Intel® Xeon® processors, the Intel Xeon D processor product family includes Intel® Virtualization Technology for Directed I/O (Intel® VT-d). Instead of being in the chipset, it is built-in.

Intel VT-d helps VMMs better utilize hardware by improving application compatibility and reliability, and providing additional levels of manageability, security, isolation, and I/O performance. With Intel VT-d hardware assistance, VMMs can directly assign devices to specific VMs to ensure high-speed data transfers and availability (Figure 5). Hardware accelerators enable this secure assignment of I/O devices, decreasing the load on the processor and accelerating data movement.

Figure 5. Intel® Virtualization Technology for Directed I/O (Intel® VT-d) enables direct assignment of devices to specific VMs to ensure high-speed data transfers and availability.

Intel VT-d improves system reliability by containing and reporting errant direct memory access (DMA) to software. It enhances security by supporting multiple protection domains under software control and providing a foundation for building trusted I/O capabilities.

A Powerful Processor for Constrained Environments

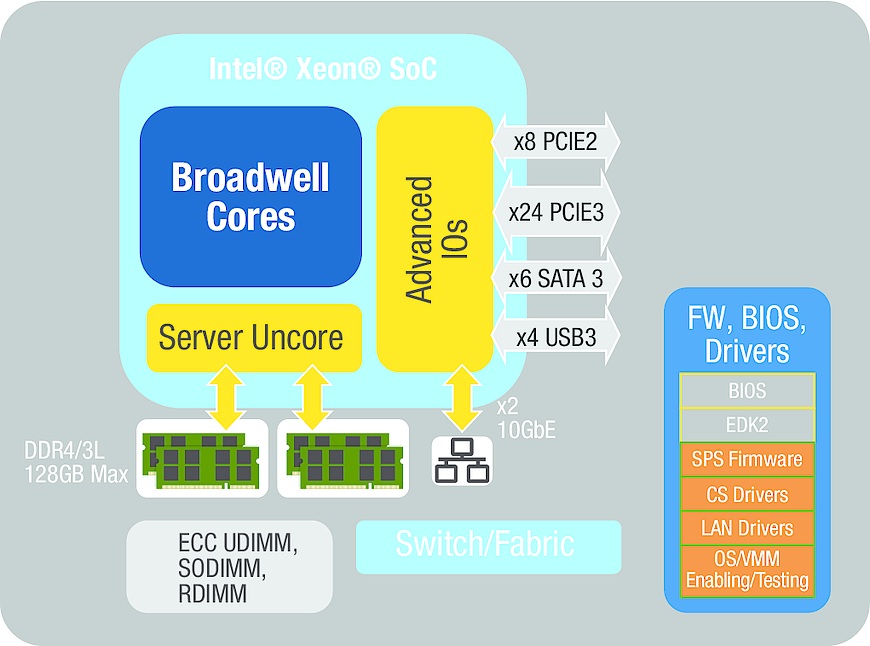

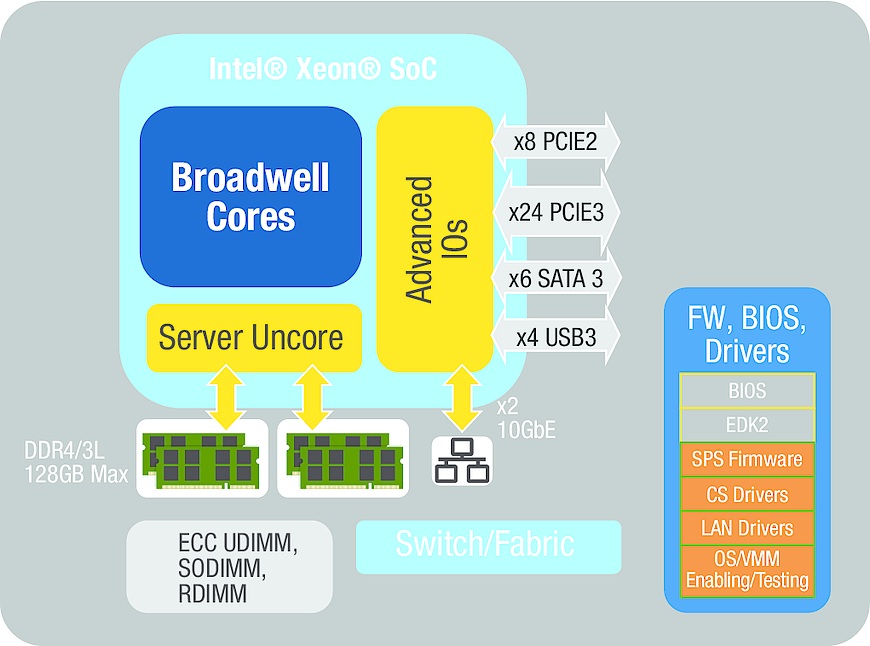

The Intel Xeon processor D-1500 product family brings the performance and advanced intelligence of Intel Xeon processors into a dense, power-efficient system-on-chip (SoC) – see Figure 6, two integrated 10 Gigabit Intel® Ethernet ports, and a thermal design power (TDP) of 20 W and 45 W, respectively. The processors can run the same instruction set as more robust Intel Xeon processors to provide software consistency from a data center to a moving train.

Figure 6. The Intel® Xeon® processor D-1500 product family brings the performance and advanced intelligence of Intel® Xeon® processors into a dense, power-efficient system-on-chip (SoC).

These SoCs offer exceptional node performance, up to 24 MB of last-level cache (LLC), and high-speed DDR4 memory support. The included Intel® Turbo Boost Technology 2.0 dynamically increases processor frequency to deliver an extra burst of speed when needed and increased energy efficiency for less demanding tasks. In addition, Intel® Hyper-Threading Technology (Intel® HT Technology) supports two processing threads per physical core, giving a G25A equipped with the Intel Xeon processor D-1577 the ability to run up to 32 threads simultaneously.

In addition to these capabilities, the Intel Xeon processor D-1500 product family includes advanced server-class capabilities such as:

- Enhanced reliability, availability, and serviceability (RAS) features supporting ECC memory and platform-level error management and resilience

- Intel® QuickData technology for offloading memory accesses to the SoC for fast data movement with low processor overhead

- Intel® Platform Storage Extensions to enable smarter and more cost-effective storage solutions that accelerate data movement, protect data, and simplify data management

- Intel® Trusted Execution Technology (Intel® TXT) to strengthen security while reducing performance impact

- Intel® Advanced Encryption Standard New Instructions (Intel® AES-NI) to accelerate data encryption and decryption

The SBC for Virtualization in Motion

Combining rugged design, a 3U CompactPCI Serial form factor, and an Intel® Xeon® processor D with up to 16 cores, the MEN Mikro G25A offers a compelling solution for system consolidation in rolling stock. With the growing complexity of multiple embedded systems throughout a train and the need for high data transfers, such a solution offers designers a solid platform for delivering much-needed savings in equipment, energy, and system management to transit companies.